More complex workpieces in smaller batch sizes, shorter life cycles and an intensively competitive environment determine present-day work processes in industrial production. The ability to react quickly and flexibly to market requirements is therefore an essential precondition for corporate success.

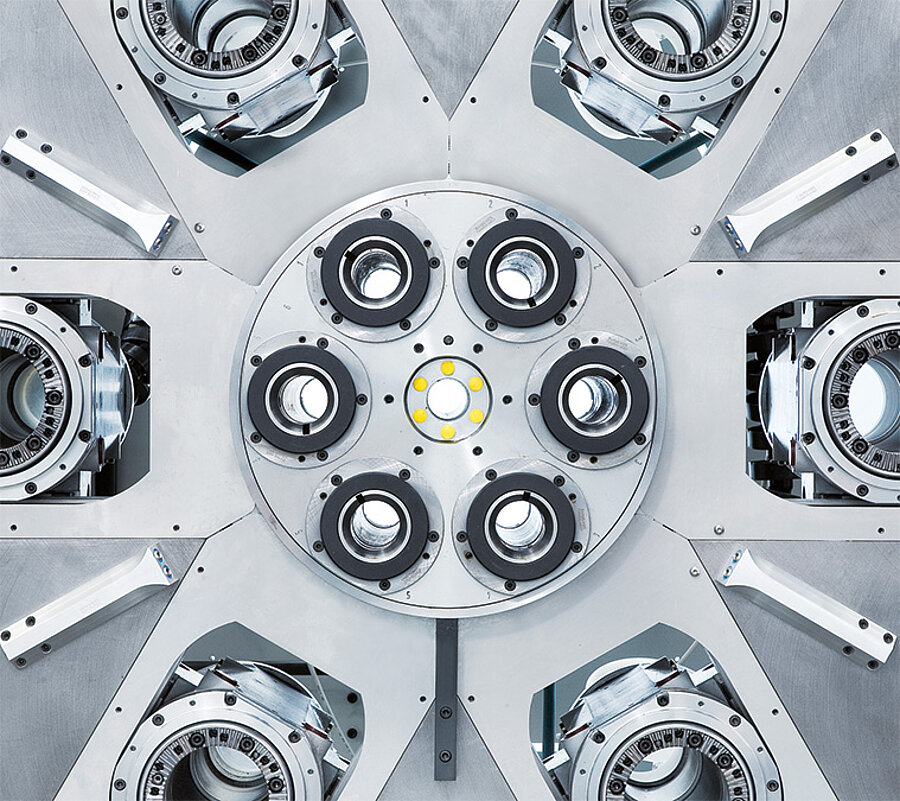

The core of the CX-, - the spindle drum-, - is positioned precisely in its position by a high-precision Hirth coupling system. Together with the stringent thermo-symmetrical structure of the headstock, this guarantees top process reliability in all spindle positions.

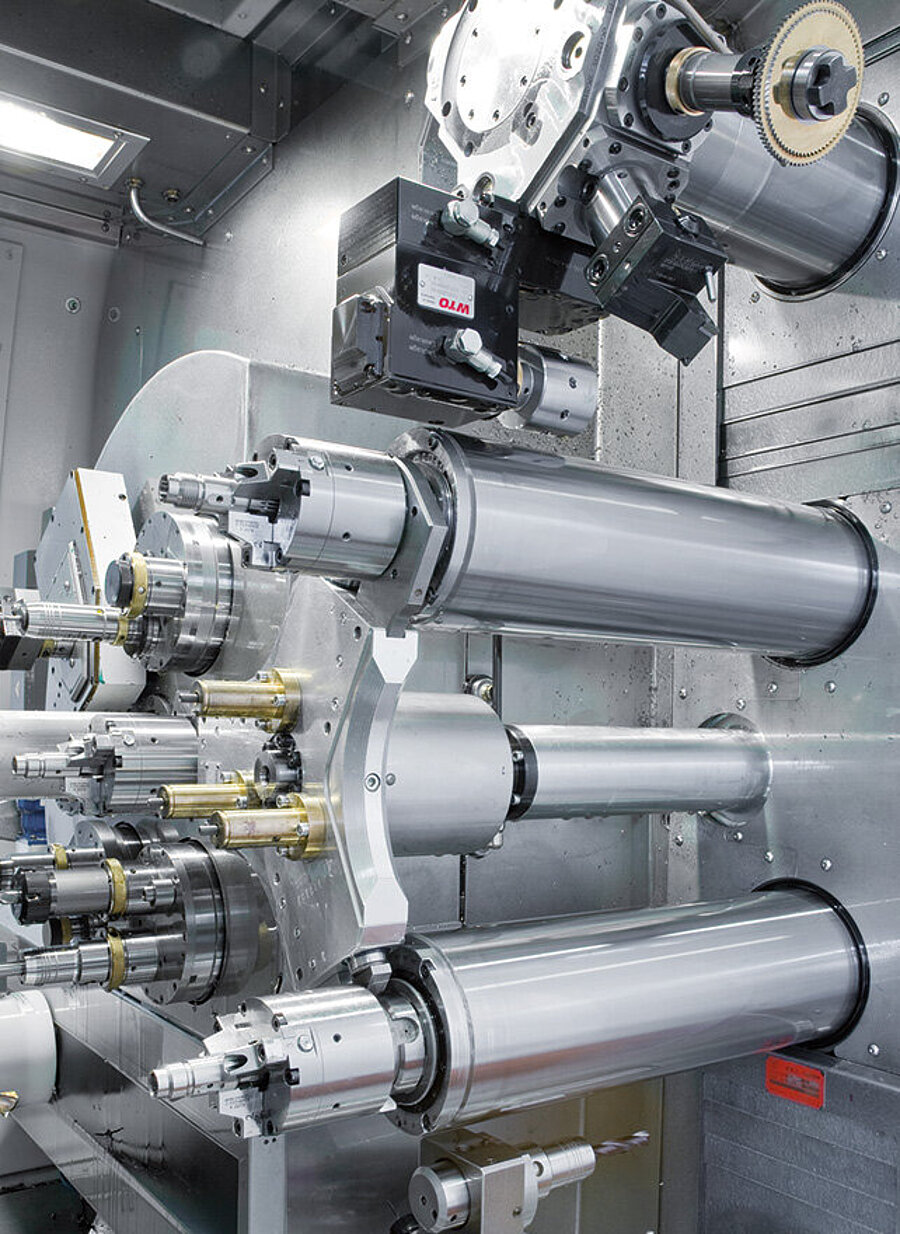

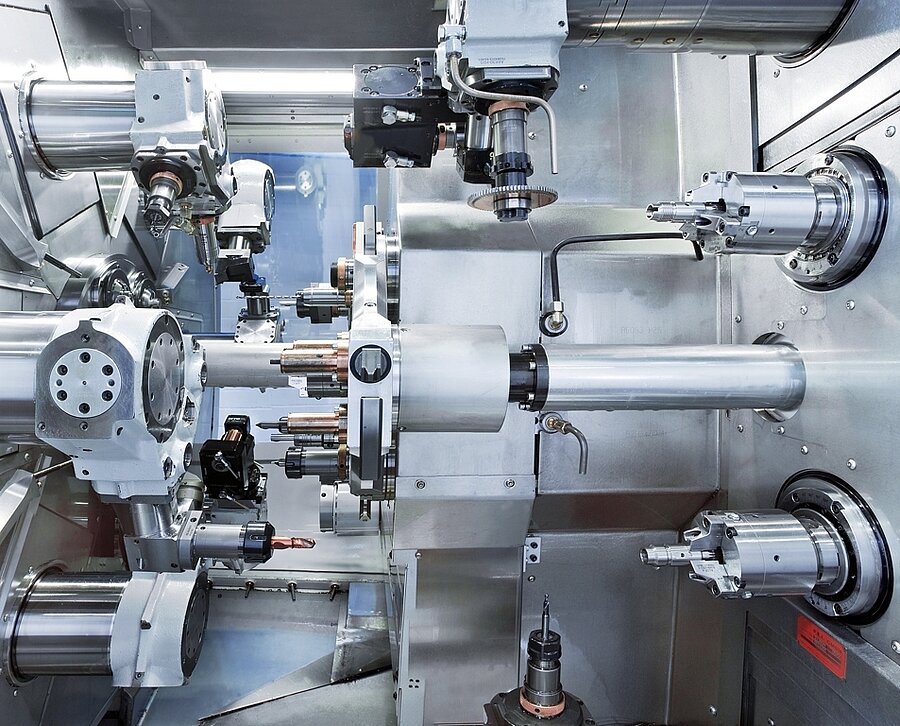

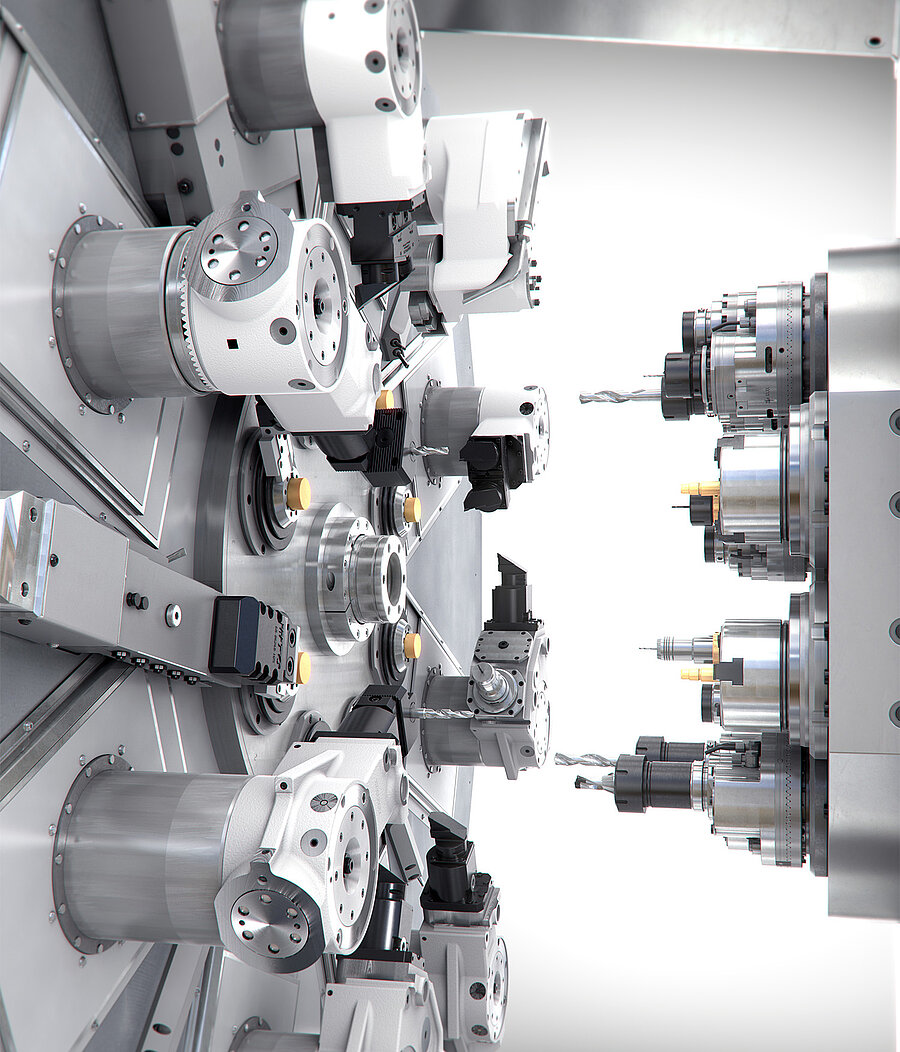

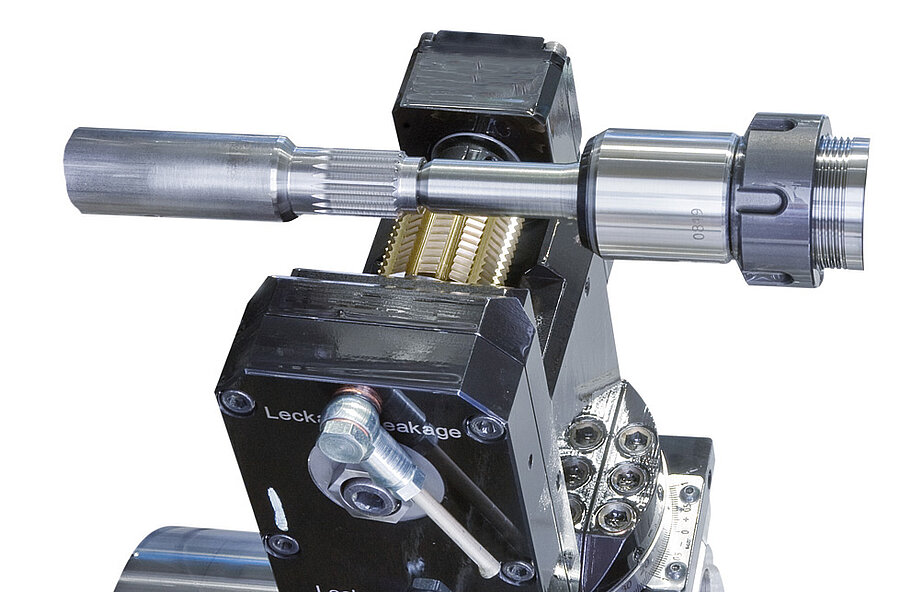

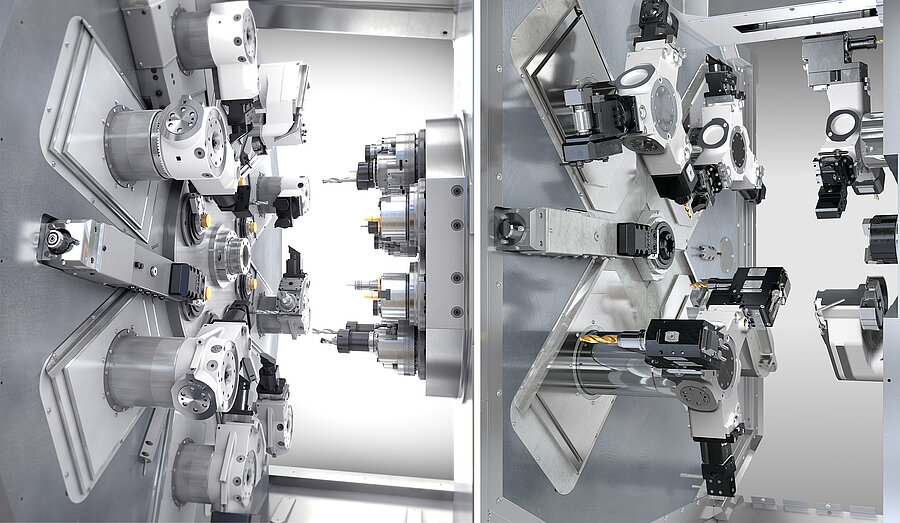

With the innovative axis structure of the cross machining units used in the multi-spindle machines for the first time worldwide, Schütte has developed a concept that combines the advantages of a rigid slide construction with flexible machine configuration.

SC7-32 | SC7-46

SC9-32 | SC9-46

AC9-36 | AC10-36

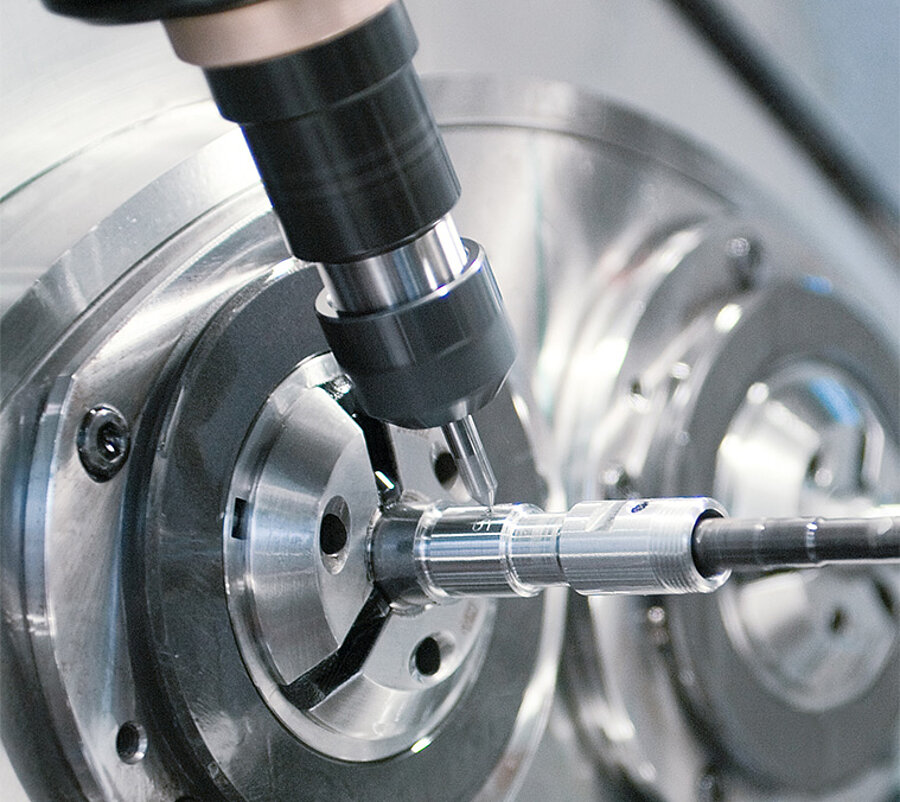

Stable, precise tool carriers and short machining times still remain important for efficient end-face grinding. The CX permits simultaneous machining on the circumference and on the front surface of the workpiece in every spindle position.

With its seven- or nine-spindle version, the CX opens up a completely new dimension in machining of the workpiece rear side. Complex workpieces can now be manufactured completely in a single operation without leaving the machine.

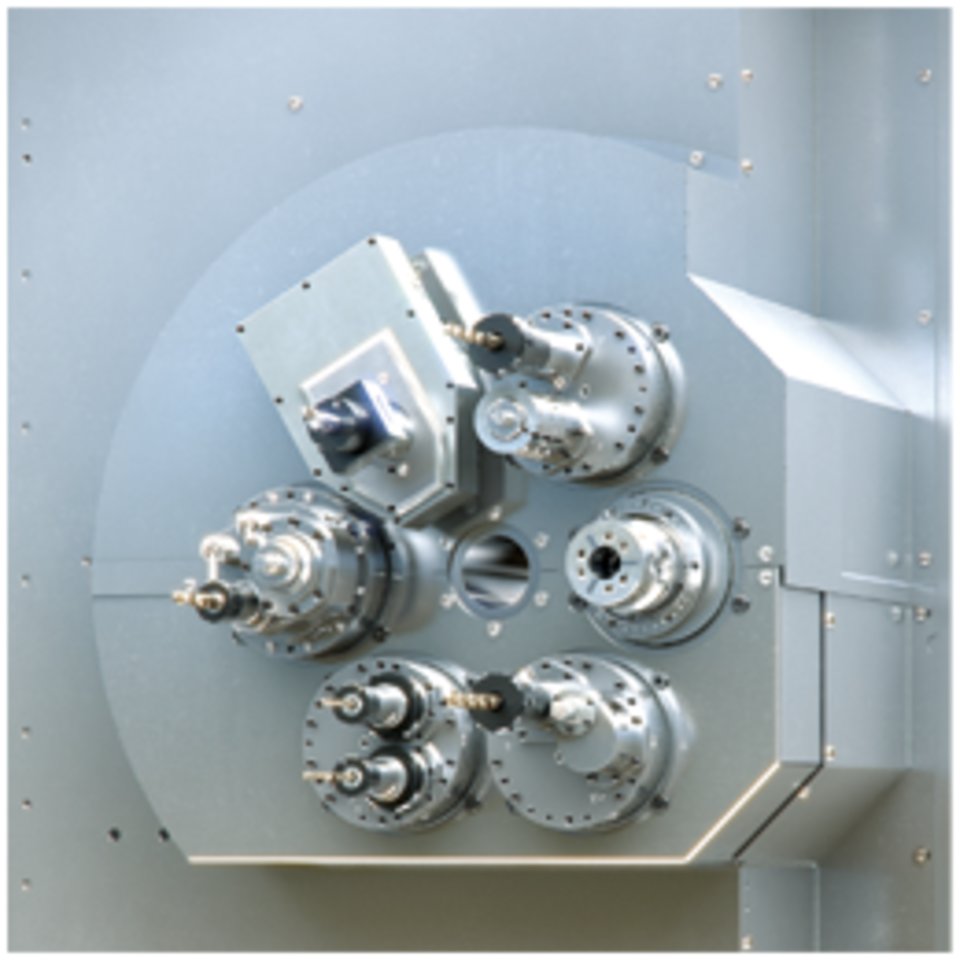

The ACX can always be adapted exactly to the requirements of the respective workpiece spectrum. It thus covers the requirements of both complex and simpler workpieces with little machining.

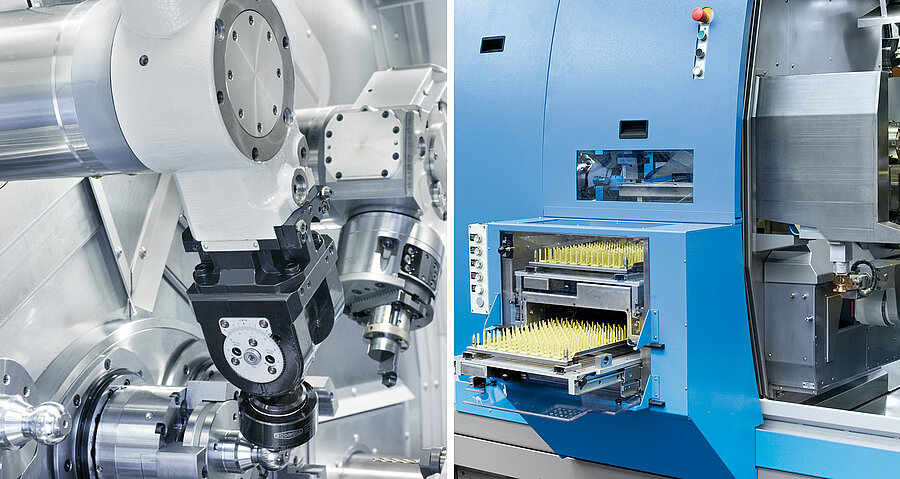

Regardless of the choice of starting material - bars, bar cut-offs, cast or forged blanks - the flexibility of the CX is also reflected in the available clamping concepts. The freely selectable design as a chuck, bar or magazine machine enables the machine to be adapted to a wide range of production concepts.

The CX also offers intelligent solutions in material transfer through the machine. The requirements of the different machine versions – collet or chuck – require adaptable material workpiece discharge versions. In this sense, the modular machine design of the CX generation allows you to consider the characteristics of the raw material (e.g. bars, bar sections, forging or cast blanks), workpiece weight and size as well as material ejection (random, aligned or damage-free).

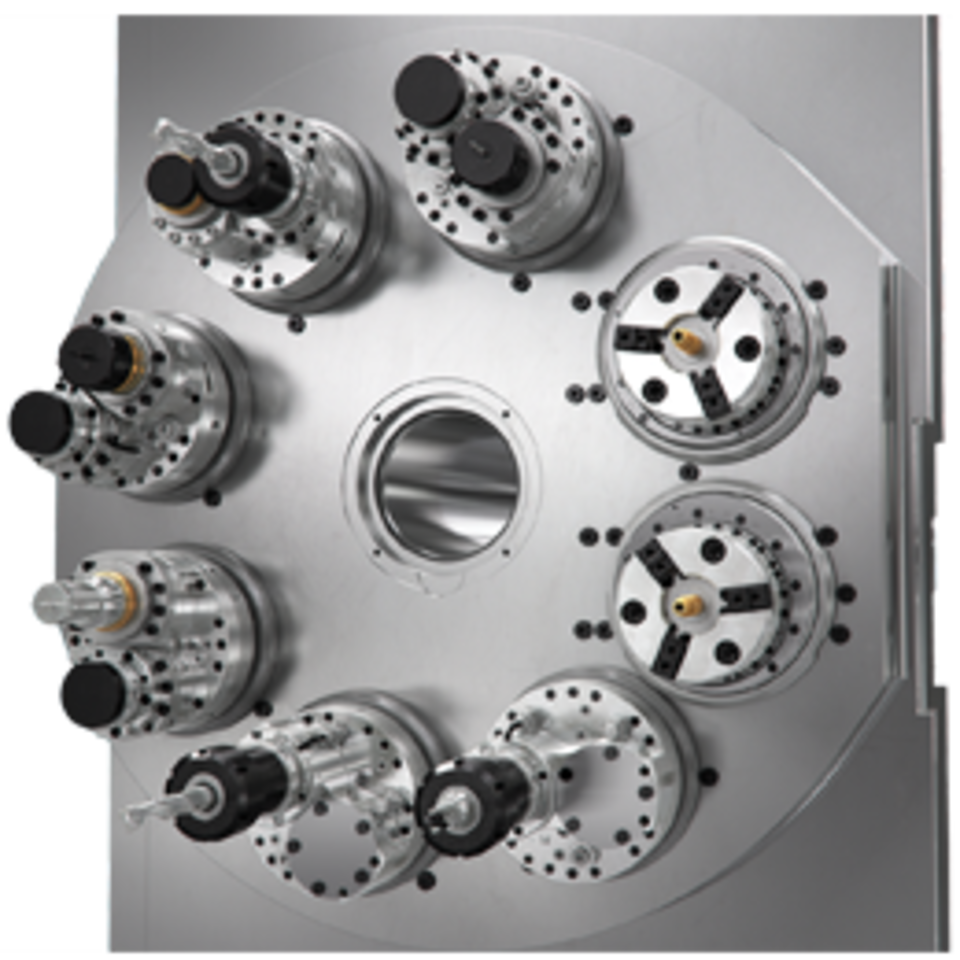

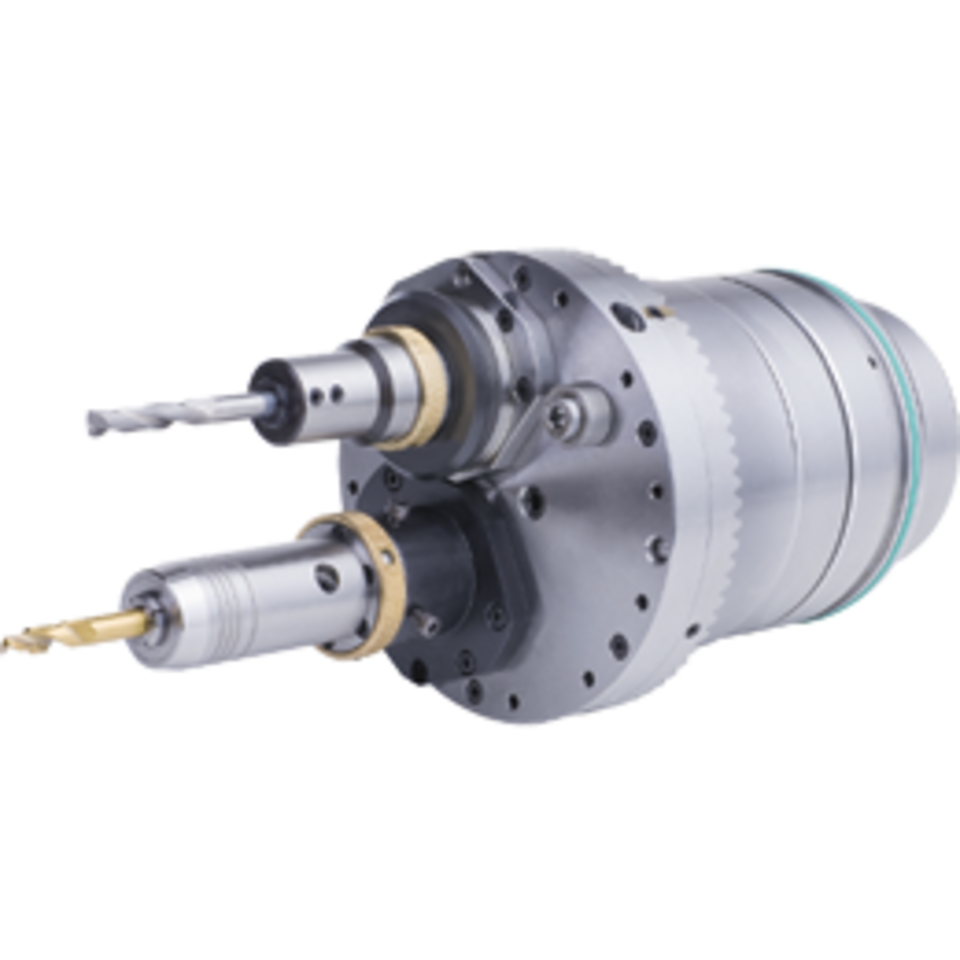

We have also implemented the concept of freedom in the modular tool system of the CX. In both longitudinal and cross machining, tool units can be used with one or more rigid or driven tools, or in combination.

tool heads longitudial - rigid

tool heads longitudial -driven

tool heads longitudial - 2/3-fold

tool heads cross - rigid

tool heads cross - driven

tool heads cross - 2/3-fold

Even with their basic equipment comprising CNC compound slides for longitudinal and cross machining as well as the optional Y- and C-axes, the multi-spindle automatic lathes of the CX generation already have versatile applications. With standard auxiliary devices for special machining tasks, the application field of this series can be expanded almost without limitations. Complete machining of turned parts with milling cuts, gearing, complex extensive front and rear-side machining, top precision and reproducible quality in interaction with extremely short machining times can thus be implemented on our multi-spindle automatic lathes in the CX generation.

The CX control system makes no compromises. It works through the widest possible range of machining programs reliably, precisely and in extremely short cycle times. Before machining starts, it supports users with intuitive dialogue, templates and information on tooling, setting work, operation, maintenance and service of the CX multi-spindle automatic lathes. Parallel to these tasks, safety functions integrated in the control system protect operators and prevent damage to the machine.

With its CX series, Schütte realised the vision of a multi single-spindlle machine or multi-station machining centre for the first time. The diversity of the machining options of a multi-spindle machine is combined with the simple setup and operation of a single-spindle machine.