The ECX combines the flexibility and simple handling of single-spindle automatics with the productivity of multi-spindle automatics and thus closes the gap between the two worlds.

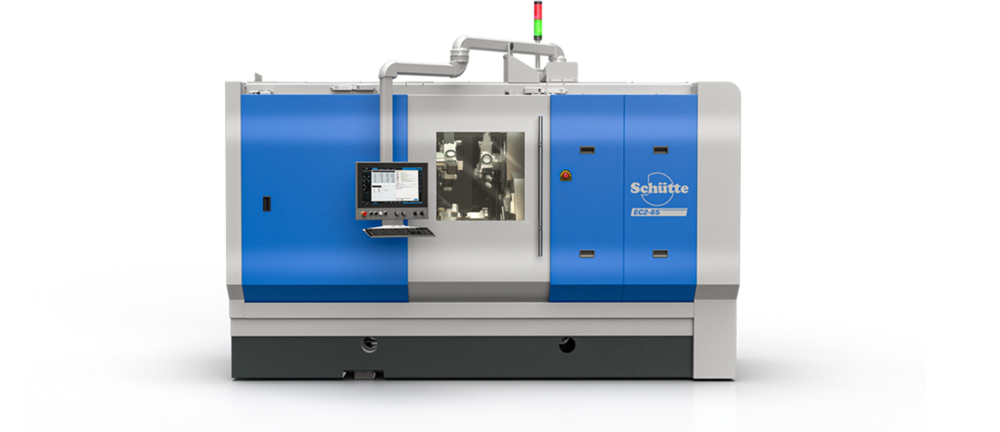

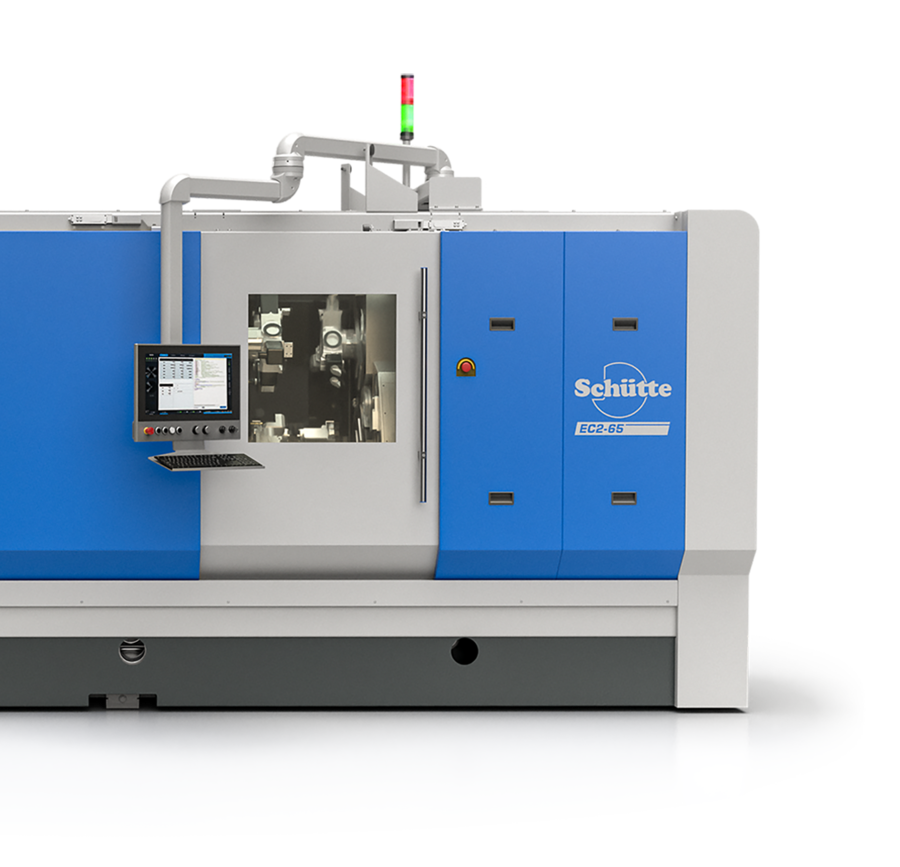

Decreasing batch sizes due to the individualisation of products and just-in-time production present industrial manufacturing with new challenges in competition. With its new ECX series, Schütte offers the perfect solution to this: a highly productive, new single-spindle automatic for batch sizes that are below the practical or economic application limit for multi-spindle automatics. The ECX is perfectly suitable for the complete machining of complex workpieces in medium batches sizes and with new materials. It combines the flexibility and simple handling of single-spindle automatics with the productivity of multi-spindle automatics and thus closes the gap between the two worlds.

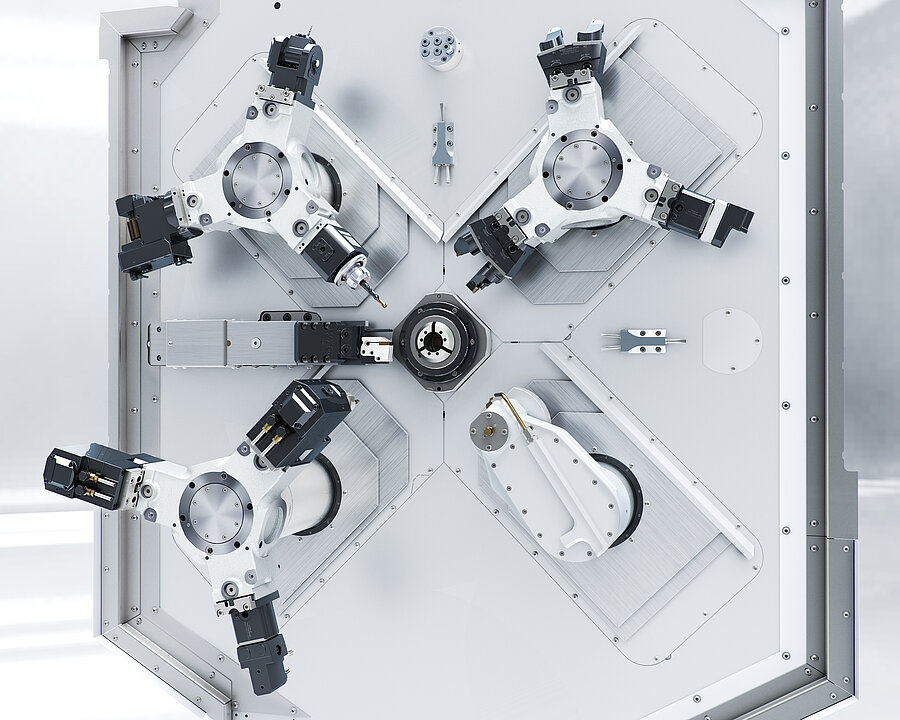

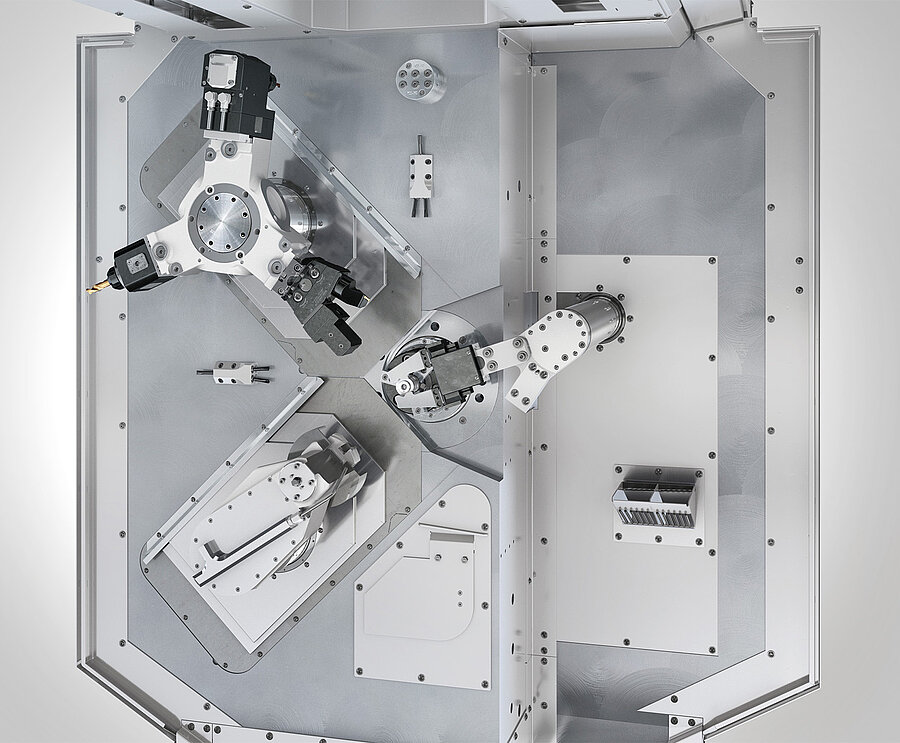

The unique and completely new machine concept of the ECX is based on established components and

functional units and puts the philosophy of parallel machining and reduction of non-production times

consistently into practice. The optional interface system ensures the fast and precise replacement of

individual devices and the modular structure guarantees simple conversion or retrofitting.

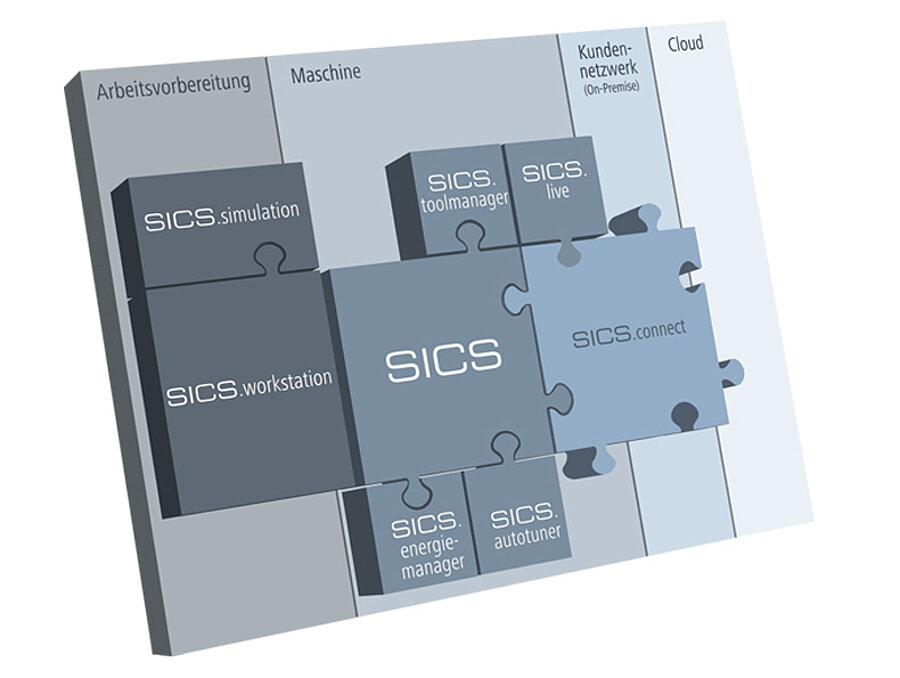

The established SICS software supports machine users with the configuration, programming and production with the machine. The familiar SICS software modules are also available here and make a step-by-step entry to Industry 4.0 applications possible.