The user-friendly software SIGSpro from Schütte allows us to react quickly and customer-specifically to your requirements. Machine functions and operation are also always ideally tuned to one another.

As our customer, you receive a complete solution from a single source, the handling of which is easy to learn, which expands to accompany new requirements and, thanks to effective services, offers process reliability in production over a long period.

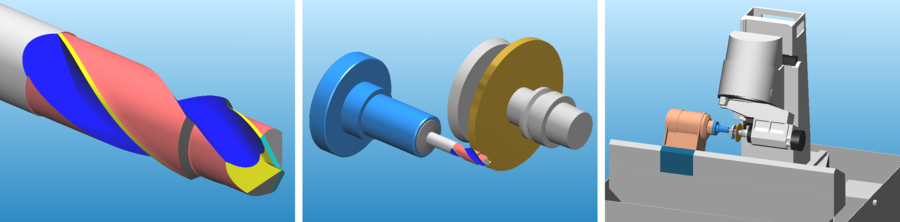

SIGSpro provides you with a large supply of grinding operations, which is continuously expanded and adapted to meet market requirements. The individual grinding operations are freely combinable and can be used as often as desired in a single production sequence. For tools with differently designed cutting edges, you can switch all grinding operations on and off tooth-specifically or assign with tooth-specific parameters. You can also vary many parameters, e.g. clearance angle and rake angle, along the cutting edge.

If a specific machining version has not been included in our program, you can either select a "free grinding path" or add the required grinding operation yourself to the operation pool in the form of a "free operation".

The high variability of SIGSpro was formulated by one of our users in a professional article in an accurate and persuasive manner: "The tool that can't be produced with SIGSpro has not yet been invented."

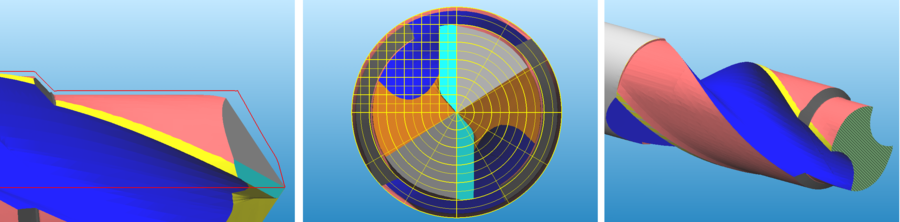

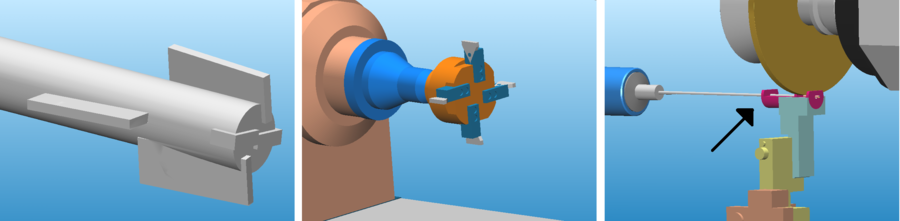

The integrated 3D simulation means that your production is on safe footing right from the first workpiece. Directly after parameter input, the programmed workpiece is displayed and can thus be controlled. In addition to the workpiece, as an option you can also fade in the grinding wheel, the grinding wheel set, the clamping device or the complete grinding machine. In the selected detail display, you can now also run the grinding process or parts of the grinding process.

In addition to the presentation of the workpiece on its own, SIGSpro provides you with numerous analysis options. For rotationally symmetrical workpieces, you can calculate and display the rotation contour, in order to subsequently evaluate quickly and reliably, by turning the workpiece about its own rotation contour, whether the workpiece has been provided all round with a sufficiently large clearance angle. You can use a freely parameterisable grid to measure angles, linear dimensions or land widths. You can apply all analysis functions to the workpiece or to freely definable cuts through the workpiece.

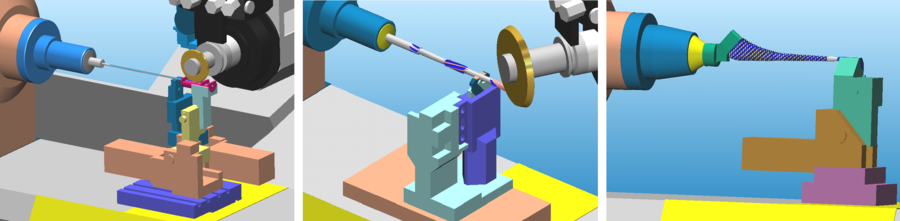

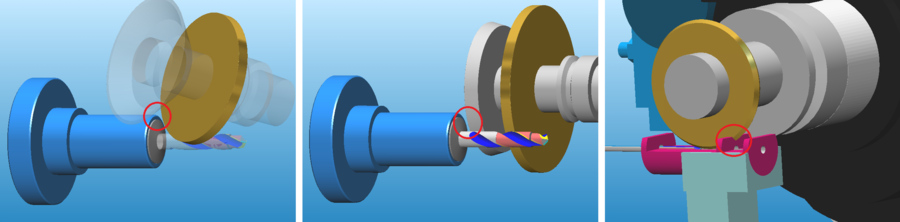

To monitor and safeguard the production sequence in the machining area simulation, the set configuration of the machine including the clamping devices and clamping aids, such as support or tailstock, are represented realistically.

You can check grinding programs generated by SIGSpro for possible collisions. When doing this, you can set which machine components are to be checked and with which safety allowances the check is to be carried out. If you have clamped several grinding wheels on one arbor, the passive grinding wheel will be regarded as a part of the arbor. This means that you will also be notified of collisions between the passive grinding wheel and the workpiece.

Even if you are using individually adapted clamping devices or aids such as tailstock centres, sleeves, half-shells or prisms in conjunction with the support , you will benefit from the 3D collision monitoring. For this purpose, SIGSpro provides you with a 3D Editor with which you can create these components and incorporate them in the collision monitoring.