Schütte offers a comprehensive product range of highly productive multi-spindle automatics, in which high-grade, multifaceted production steps run parallel to one another to produce a workpiece.

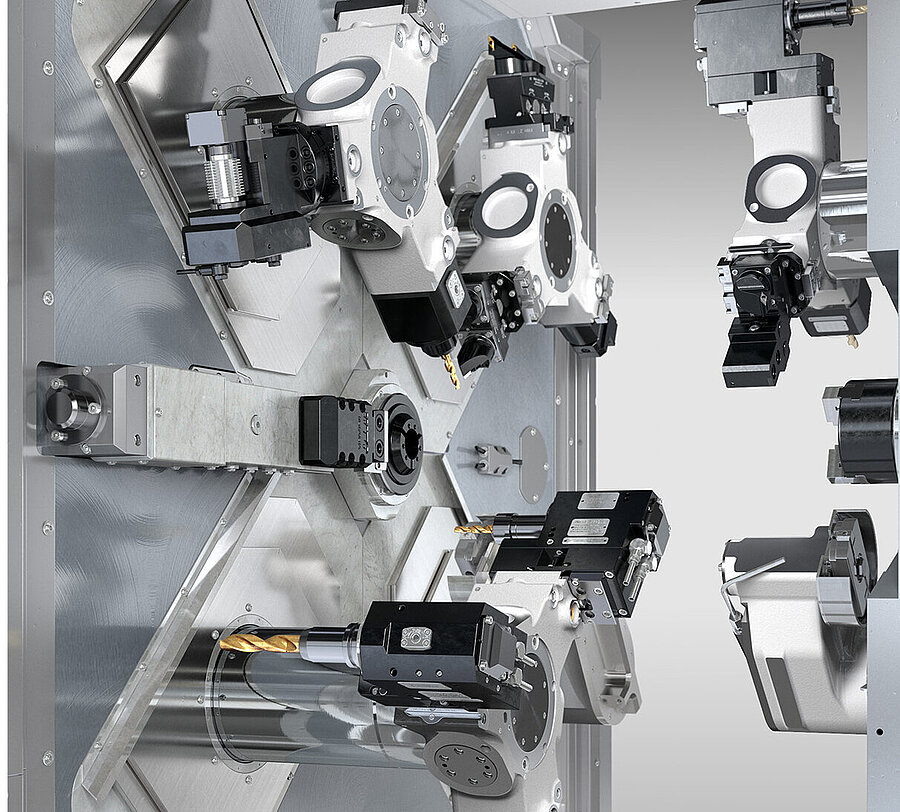

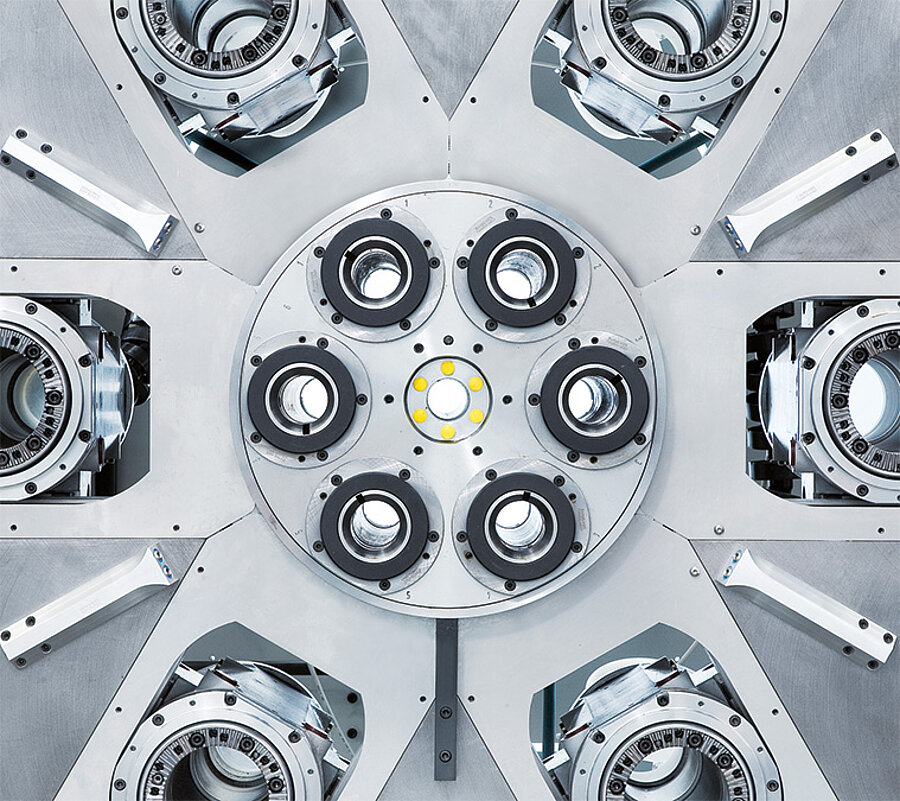

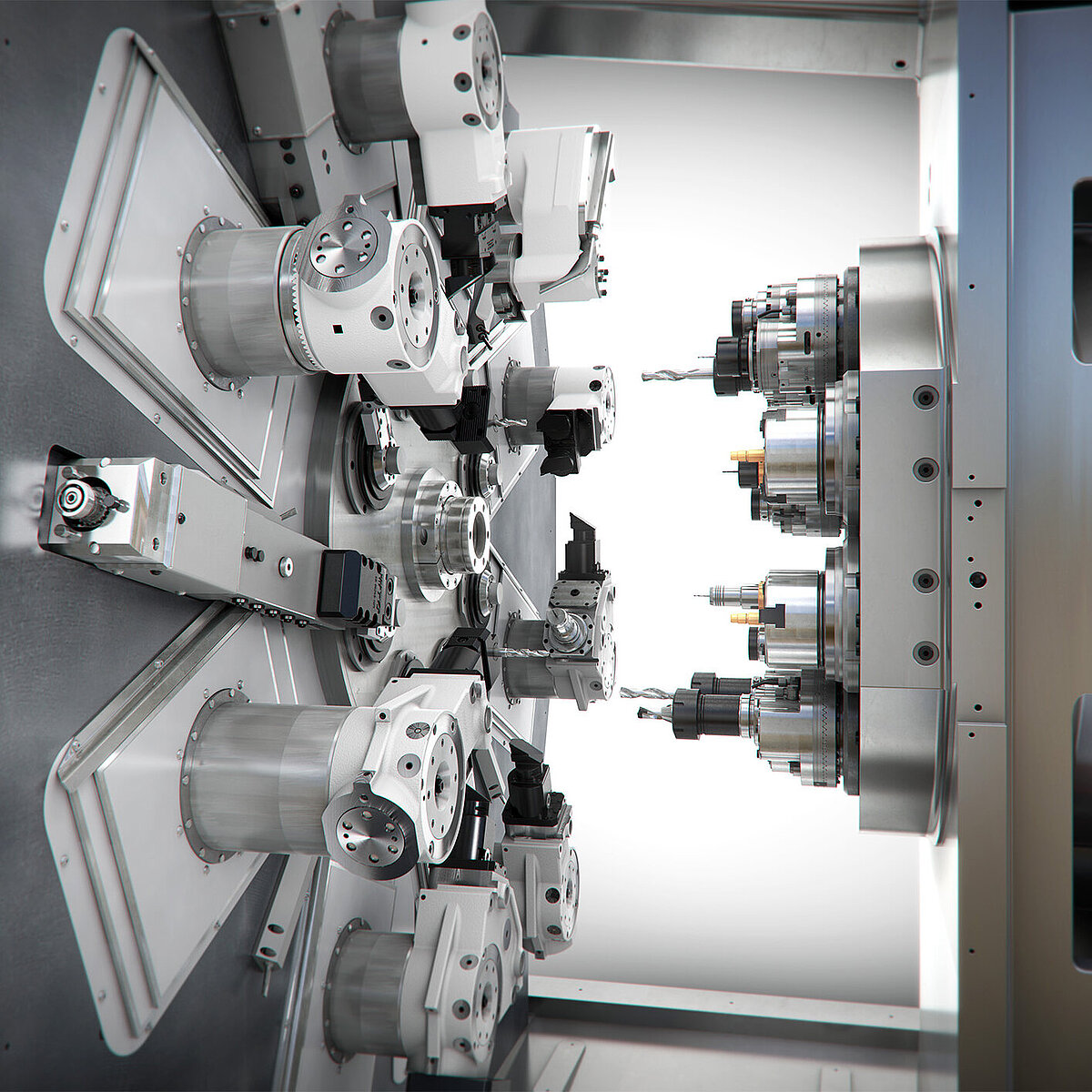

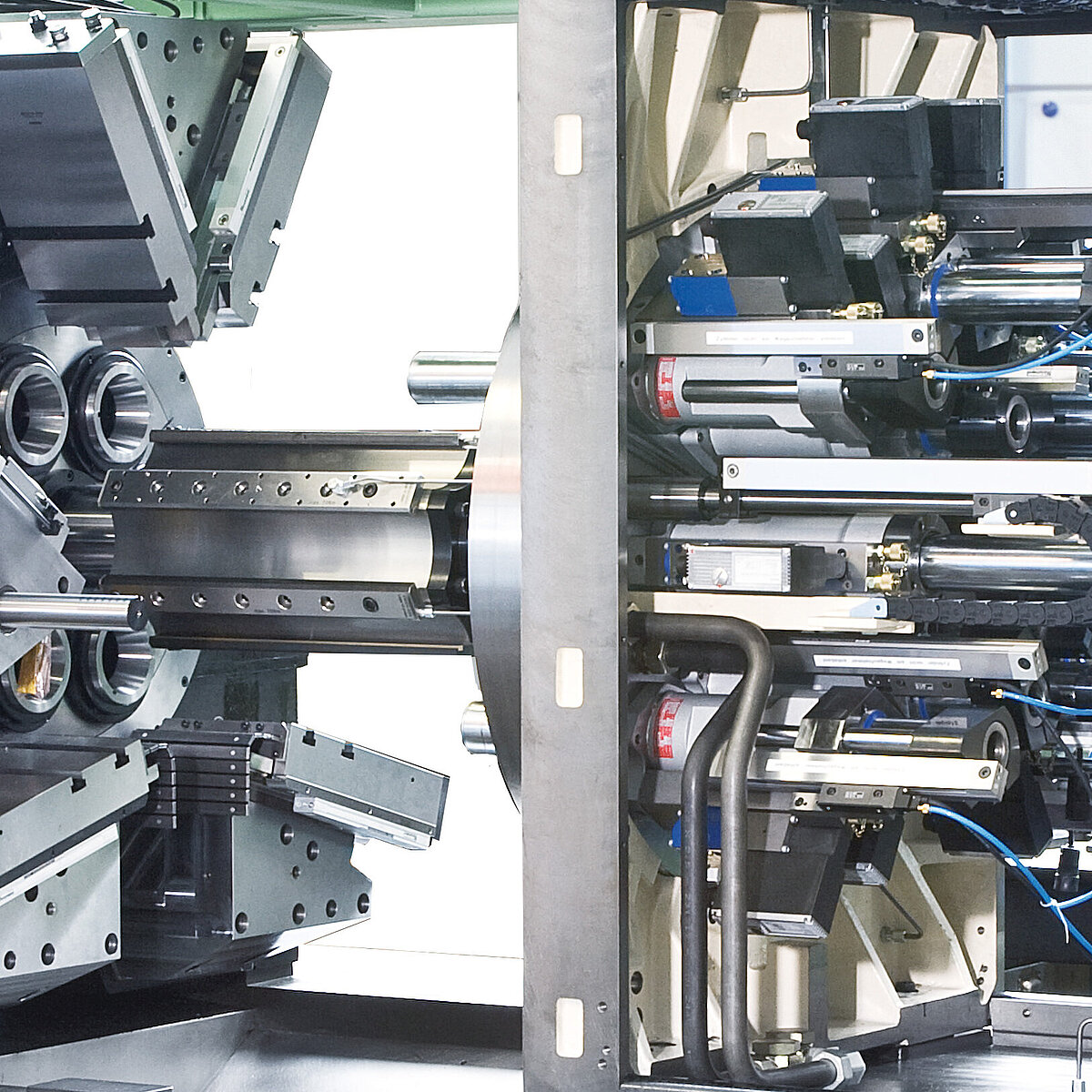

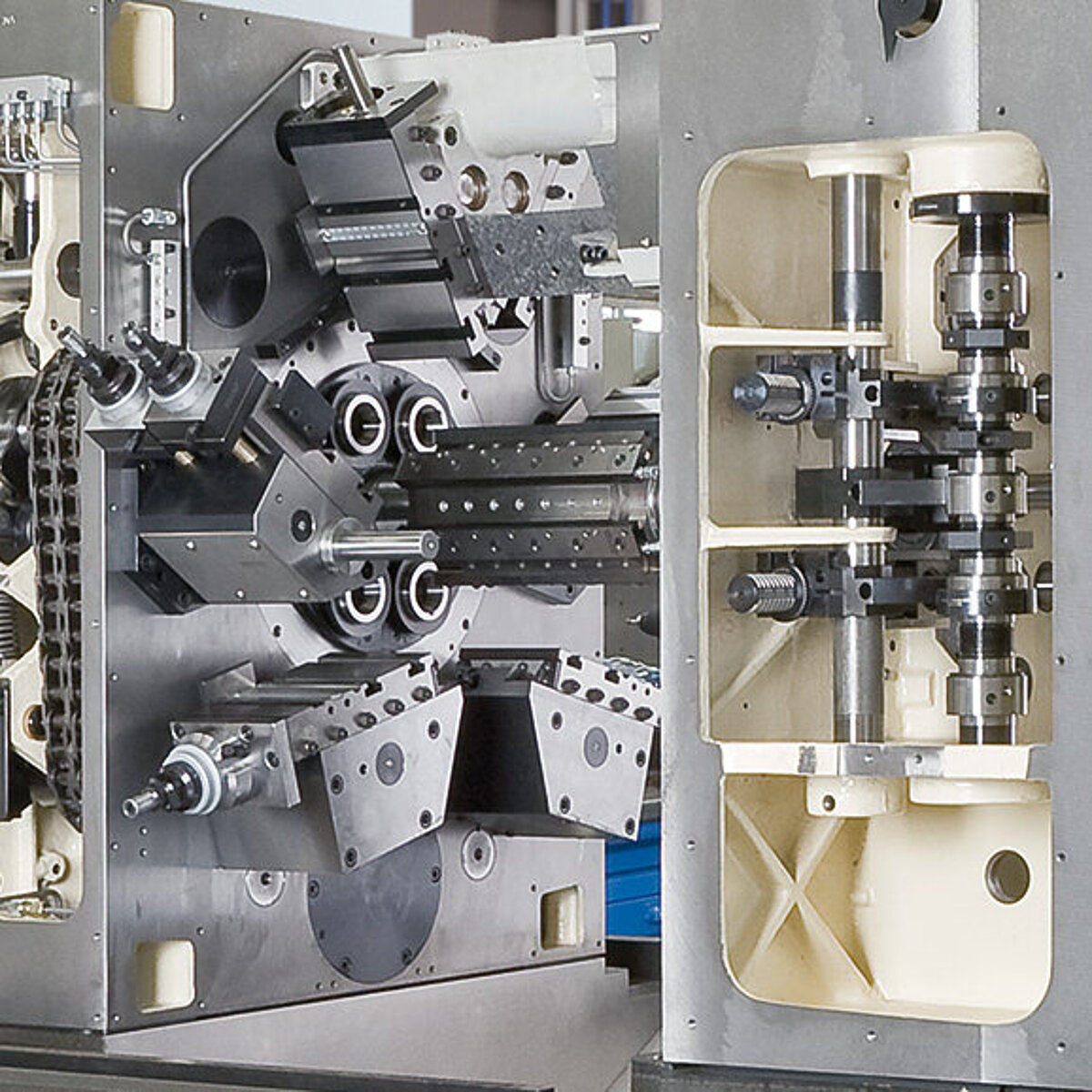

The production process is spread over several machining spindles. The machining spindles arranged in a spindle drum are switched by the clocking of the spindle drum in a sequence of machining stations. Six-spindle machines, for example, have six machining stations. Through the use of corresponding slide units, in each machining station two tools usually work at the same time on the workpiece. In the example of the six-spindle machine, this means that 12 tools, which manufacture the workpiece step by step, are continuously in operation. The productivity of a multi-spindle automatic lathe is – depending on the number of spindles and type of application – around 5-7 times higher than a single-spindle automatic lathe.

Different series, from the cam-controlled automatics to the highly flexible NC-controlled machines in all axes and spindles, form the basis for the made-to-measure Schütte solutions. Schütte offers a highly productive, economic solution that meets the respective requirements for every machining task from the machining of a 'simple' turned part to the production of complex and high-precision workpieces. Our multi-spindle automatics therefore meet the requirements of the automotive and fitting industry, general mechanical engineering as well as those related to the manufacture of hydraulic, pneumatic and electrical components.

Our Schütte Software SICS - Schütte Integrated Control System - for multi-spindle automatic lathes facilitates the operation of the machine and provides you with comprehensive support for optimisation of processes and cycle times.