Our automatics in the PC series are designed for material removal on geometrically sophisticated parts made of hard solid materials. The CNC multi-spindle automatics are designed to be robust, durable and technically flexible in production.

Machines in the PC series supply ready-to-install precision parts from small and medium batch sizes up to mass turned parts. They are used by automobile manufacturers and suppliers, in the fitting, pneumatic and hydraulic sectors and in contract manufacture.

All efficient performances need a foundation. For the integration of different processes, for the removal of tough materials, for speed, precision and reliable processes, this is provided by a robust machine structure. The modular and flexible Schütte concept is based on over 100 years of experience in machine tool construction.

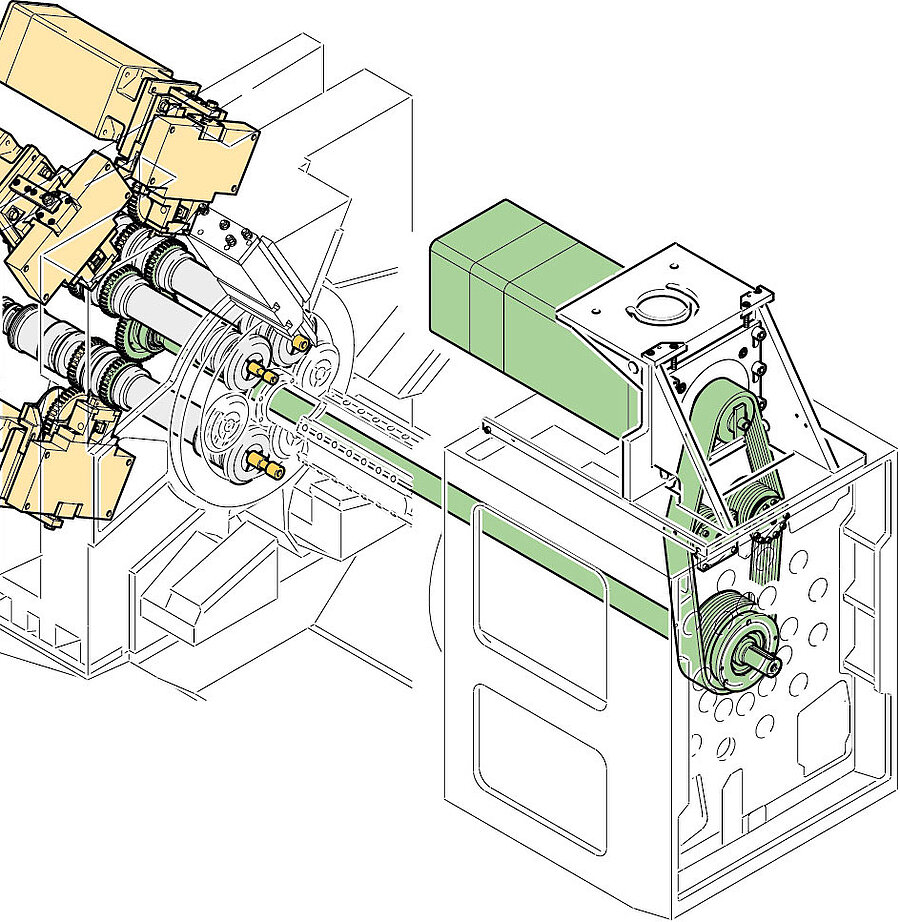

The effectiveness of a means of production depends essentially on how well the technologies used interact with one another. Schütte has developed a drive concept for the PC multi-spindle automatics that meets the requirements of both high-performance production as well as energy efficiency.

Flexibility that guarantees your competitive advantage

The cross slides in the PC series also make complex contours possible. Typical application fields for compound slide machining are contour turning and thread chasing. Any rotationally symmetrical contours, e.g. tapers, spherical shapes, undercuts and radius transitions can be produced with internal or external contours.

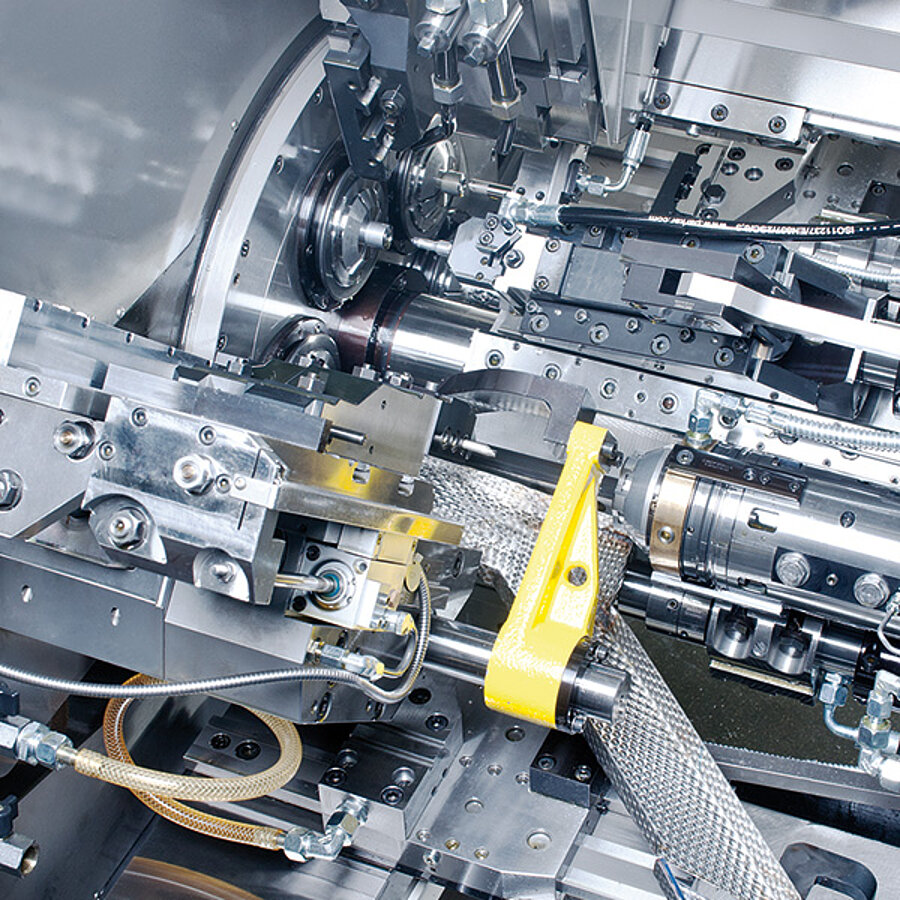

Complete machining often requires the combination of different production processes. The machining of tough and high-strength materials requires perfected, flexible material removal technology. Drives, tool and auxiliary equipment are configured to fully meet the requirements of the customer. The machine can be retrofitted at any time if the application range is extended. The PC series has a comprehensive range of attachments. The machine can thus be equipped corresponding to the machining task. This includes:

Control of 56 and more axes requires technically mature hardware and control engineering. This is particularly the case if handling and programming is not to be carried out by specialists only. The technology and operator interface "SICS 2000" is designed to make typical features, such as camshaft, cam-gear and special machining cycles available. This is supported by a flat, user-friendly operating panel. The user interface "SICS 2000" is arranged according to operating modes and operator control areas and tuned to the special requirements of a multi-spindle automatic. Interrelated processes are also grouped together in the respective menus. Programming and optimisation can be selected position-specifically according to the technological sequence and can be carried out with a high level of support for the user.