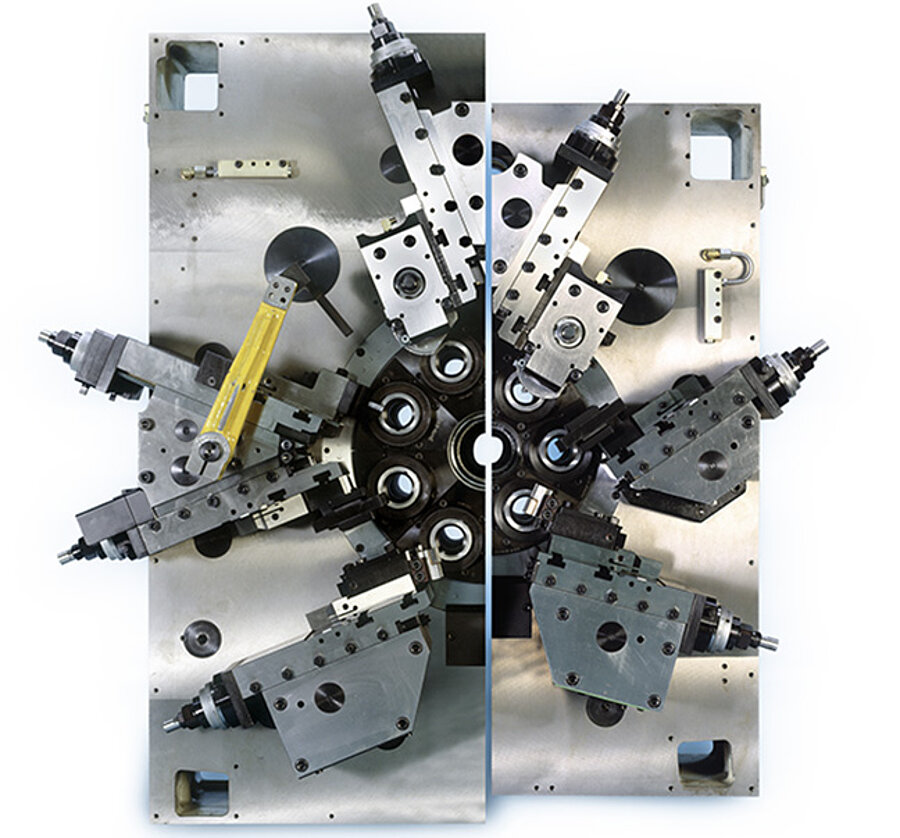

The extremely fast cam-controlled machines are ideally suited to the highly productive mass manufacture of turned parts in short part-production times. This machine concept offers even more: the G-series combines the speed and reliability of the cam drives with the flexibility and precision of CNC technology

The multi-spindle automatics in the G-series cover the range in small turned part production up to a diameter of 20 mm.

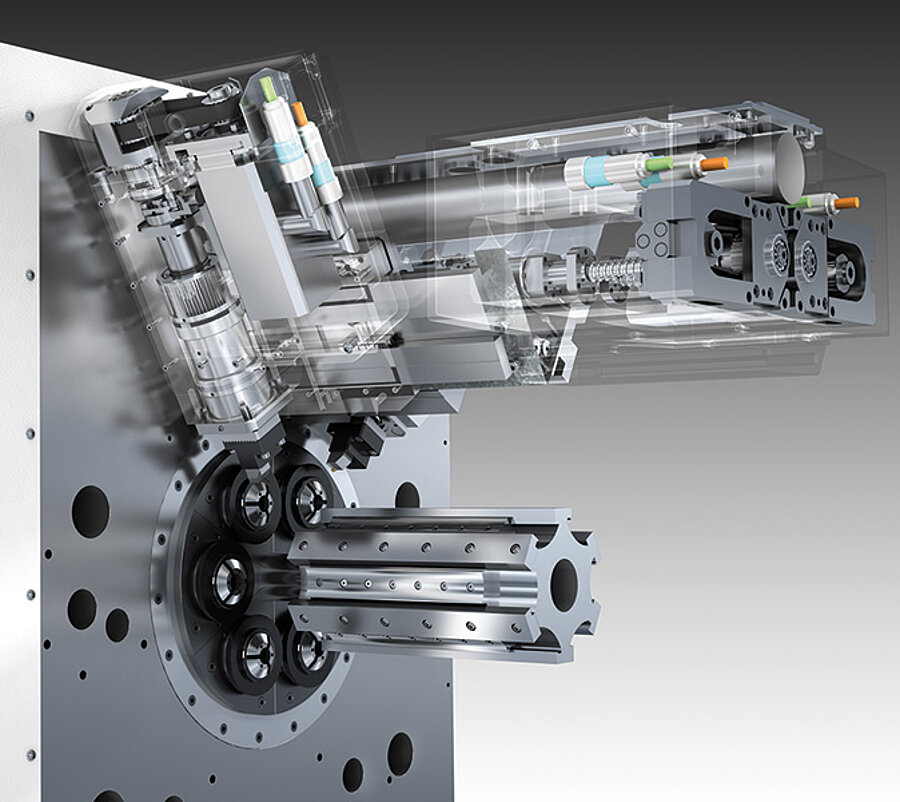

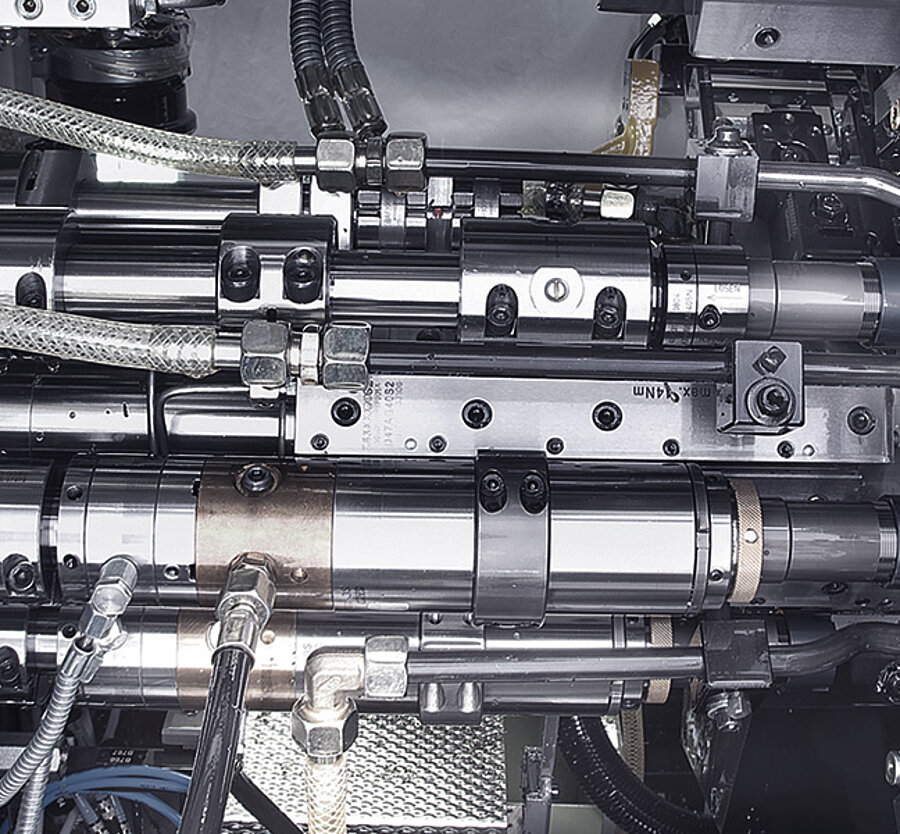

The extensive range of Schütte auxiliary devices widens the application area of the G-series towards higher part complexity. Optional attachments can be used to product surfaces, slots, threads, profiles or cross holes. In many cases, this permits complete machining of the workpieces and thus increases accuracy and economy.