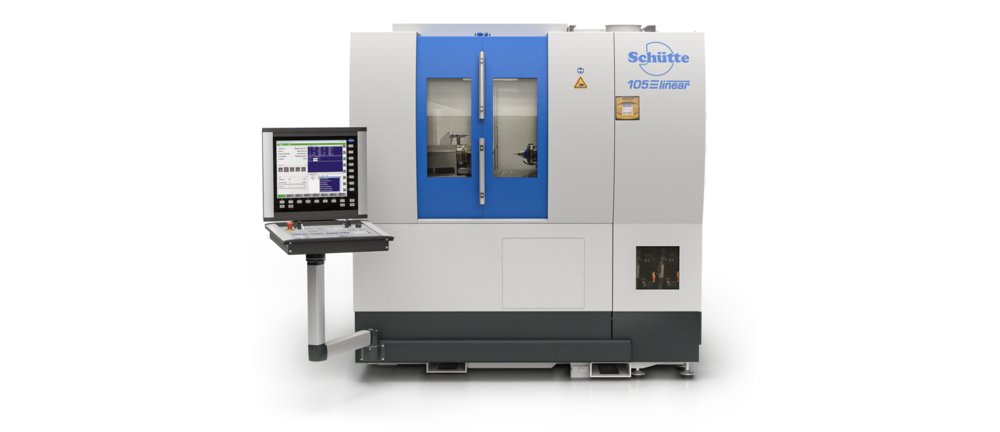

For manufacturers who produce complex tools in large quantities and with high accuracy requirements, Schütte sets new standards: The innovative, compact 105linear grindingmachine impresses with its high productivity, short cycle times and permanent precision - ona small footprint. This is made possible by special kinematics, which ensure maximumaccuracy with an innovative axis arrangement. With scalable automation solutions andintelligent additional options, the machine adapts exactly to the production requirements.The necessary robot cell is included to the basic configuration.

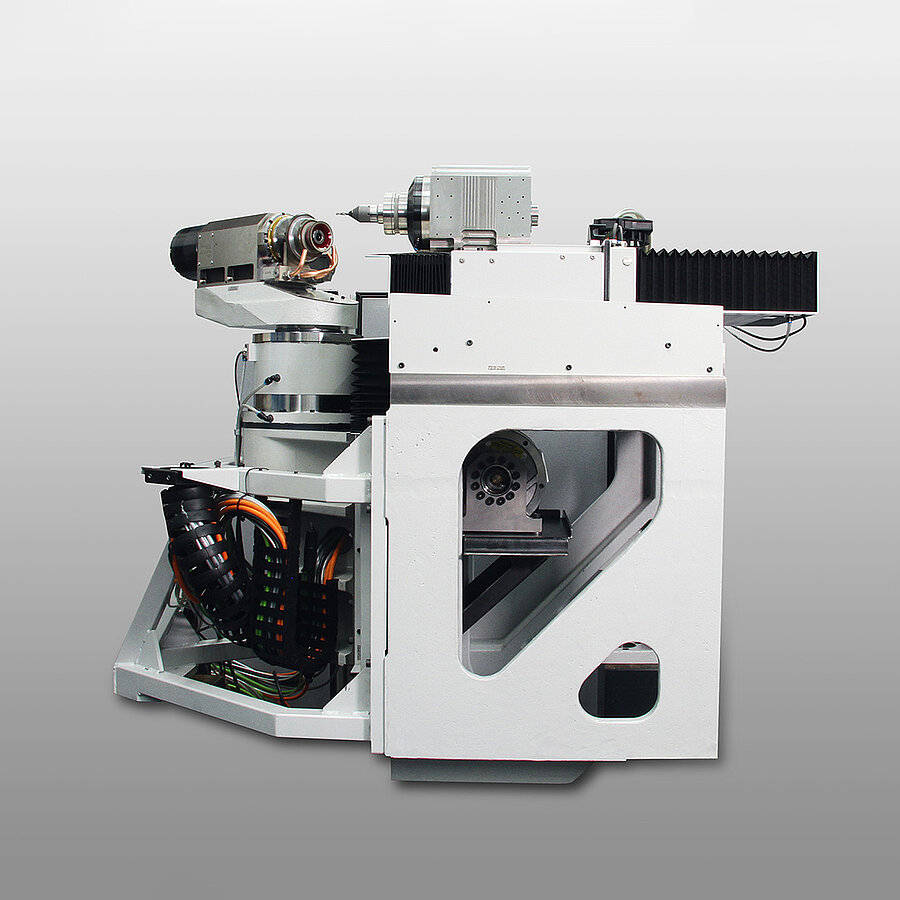

The intelligent axis arrangement of the 105linear creates the ideal conditions for high-precision machine. The unique compact design guarantees the highest static, dynamic and thermal stability and minimized power flow, dynamically moving masses and effective lever arms.

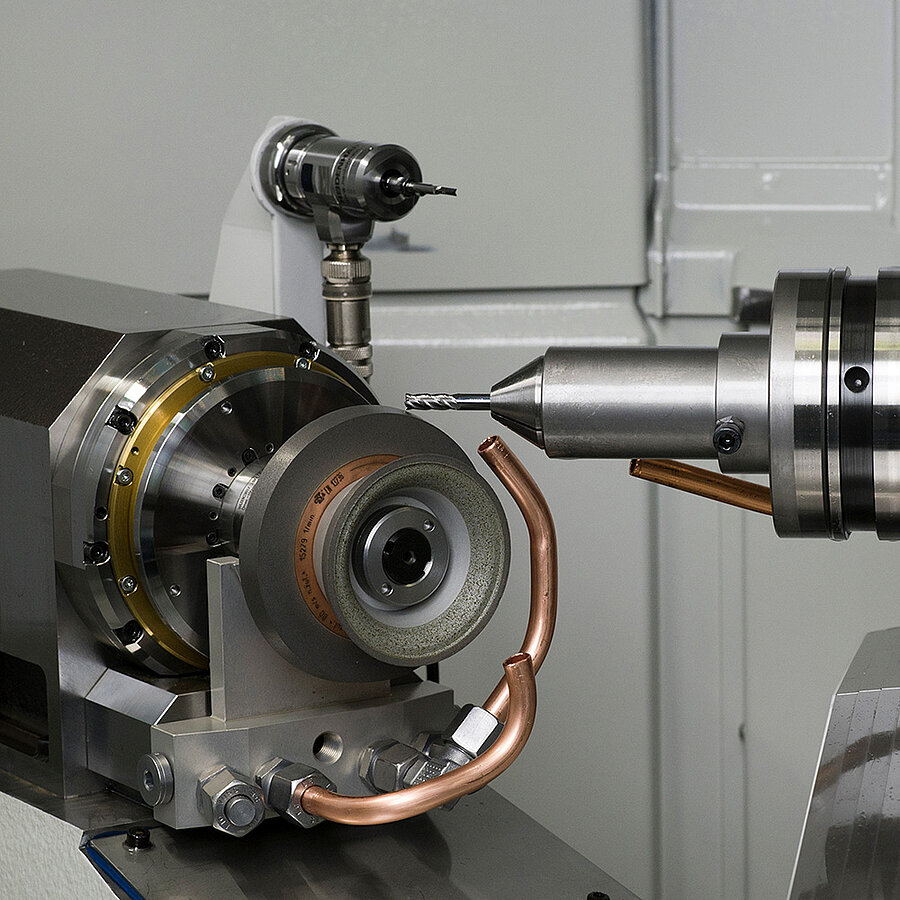

The powerful grinding spindle of the 105linear will certainly provide valuable impulses to the productivity of your manufacturing processes. The patented simultaneous replacement of grinding wheel set and associated cooling lubricant distributor ensure high flexibility with optimum process cooling.

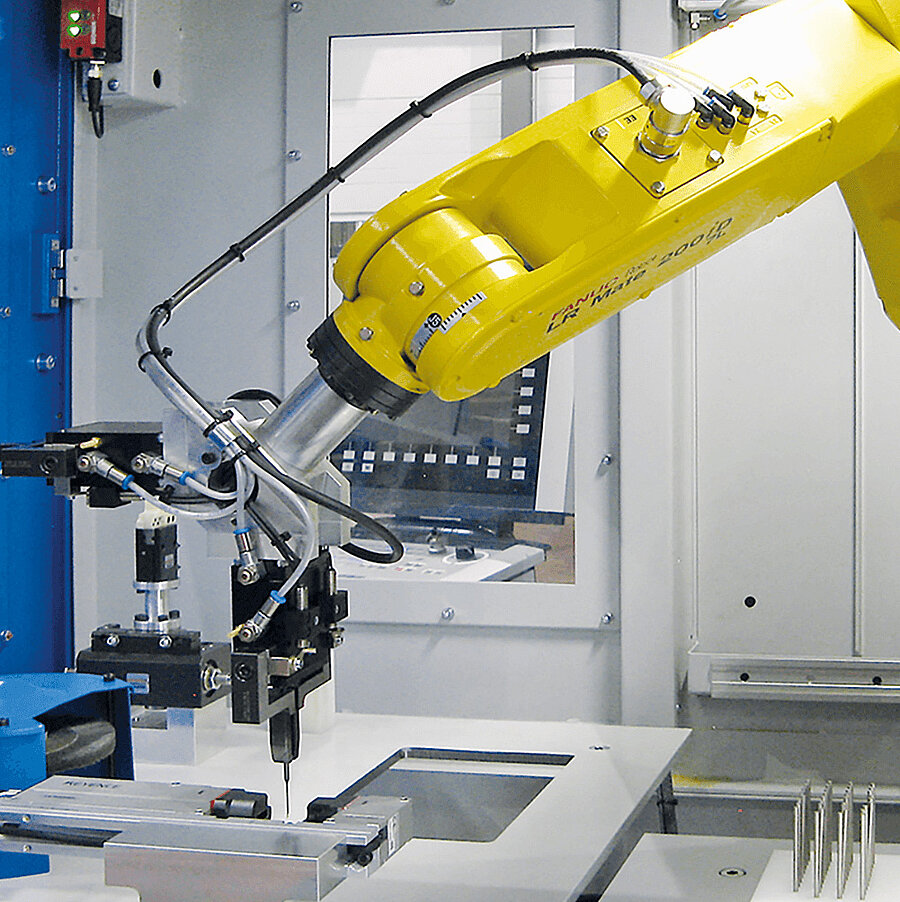

The 105linear offers automation options with which the machine can be continuously adjusted and expanded. This allows users to react flexibly on changing production requirements - over the entire life cycle of the machine.