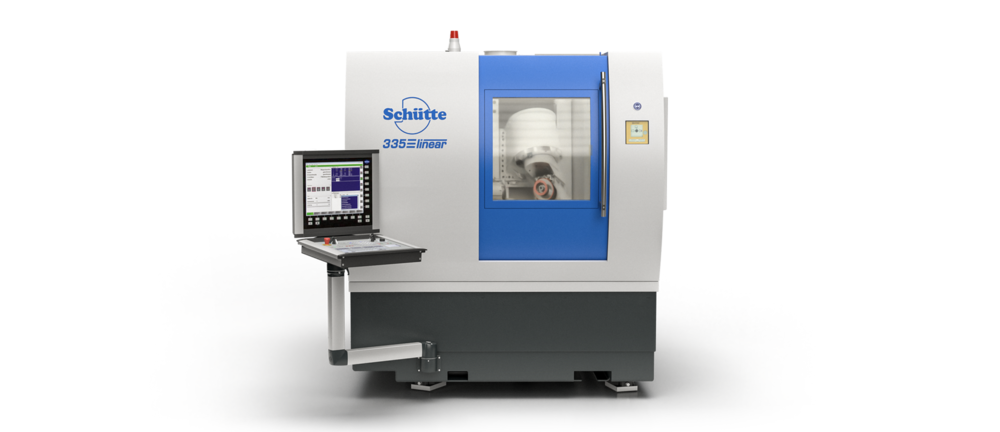

Our machines in the 335linear series are characterised by top precision, tremendous flexibility and long-term value stability. Thanks to a perfected modular system comprising additional options, you can cover the complete range of grinding applications, from the twist drill to the knee implant, from microtools to hobs, with a single machine type. The axis arrangement, which is unique on the market, with the grinding spindle inclined at an angle of less than 30°, enables an extremely compact design with optimum access and visibility into the working area. You are investing in a product that has been established on the market for many years and has been continuously developed and adapted to innovations in drive and control technology.

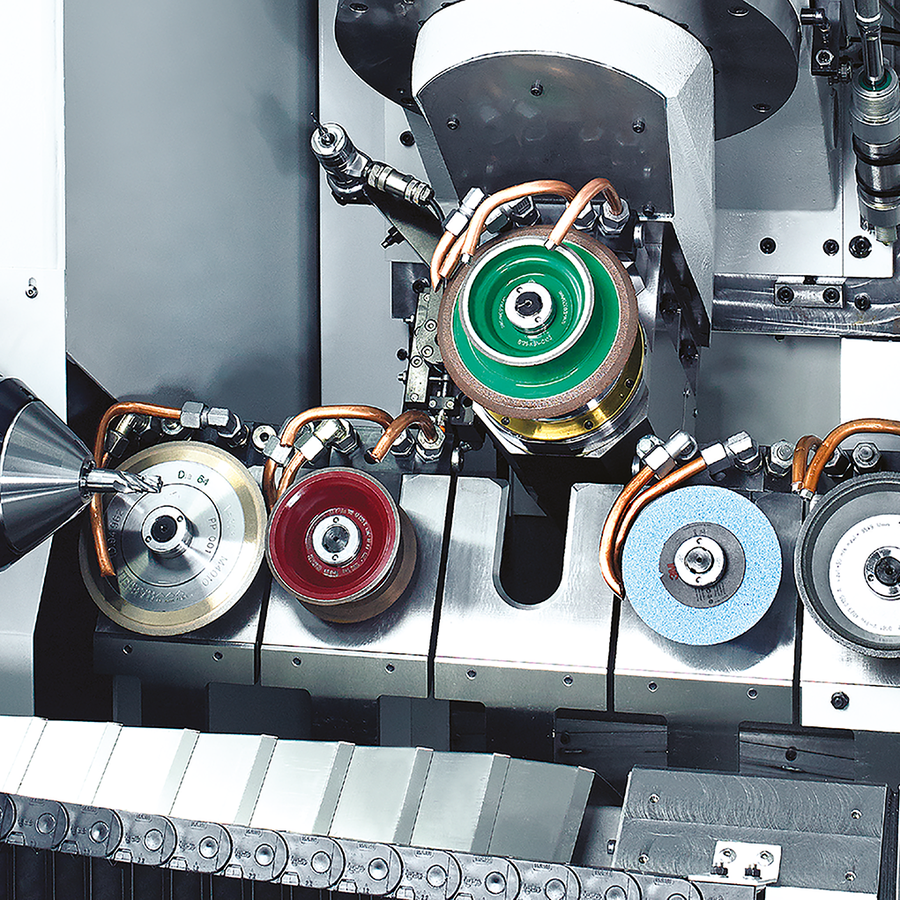

The powerful grinding spindle of the 335linear will certainly provide valuable impulses to the productivity of your manufacturing processes. The patented simultaneous replacement of grinding wheel set and associated cooling lubricant distributor ensure high flexibility with optimum process cooling.

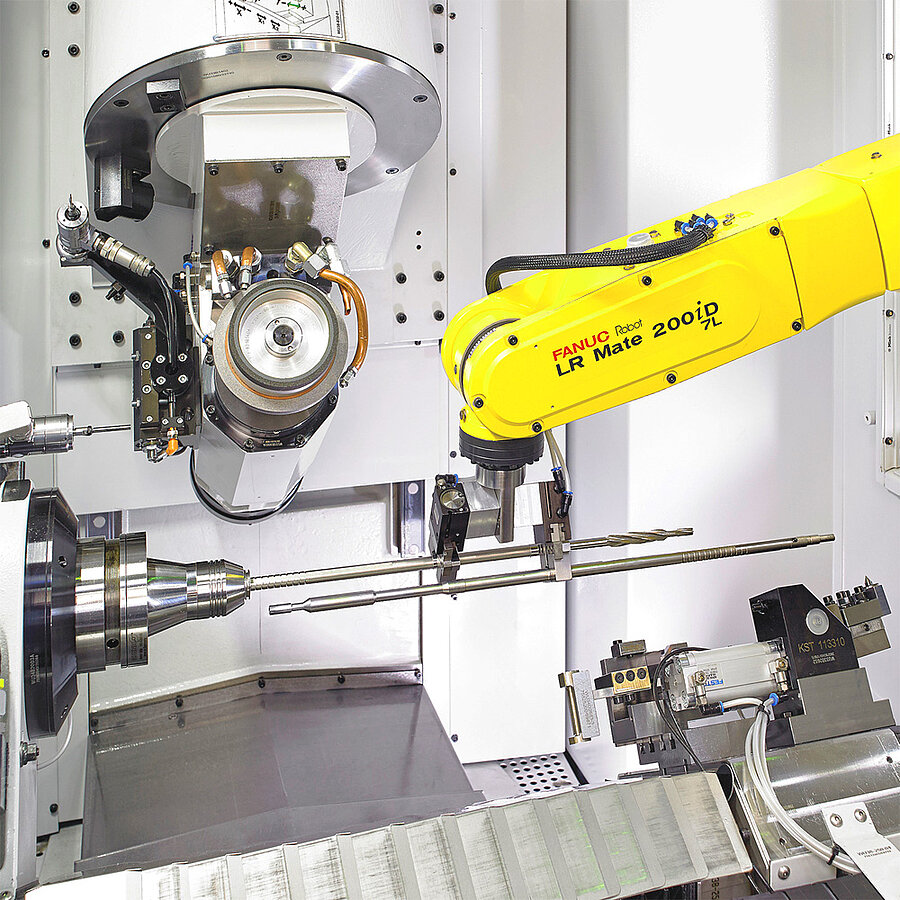

The 335linear is equally suitable for all requirements from single-part production (lot size 1) to highly optimised mass production. For this purpose, it can be automated as an individual cell and can thus operate profitably in unmanned shifts or can be interlinked in production systems. A large number of automation options guarantees you an ideal cost-benefit ratio for each scenario.

Even in case of extreme accuracy requirements, the 335linear represents a future-proof investment. In the course of the successful completion of many demanding projects, we have developed a large number of options that can be used to guarantee initial and continuous accuracy of your production.

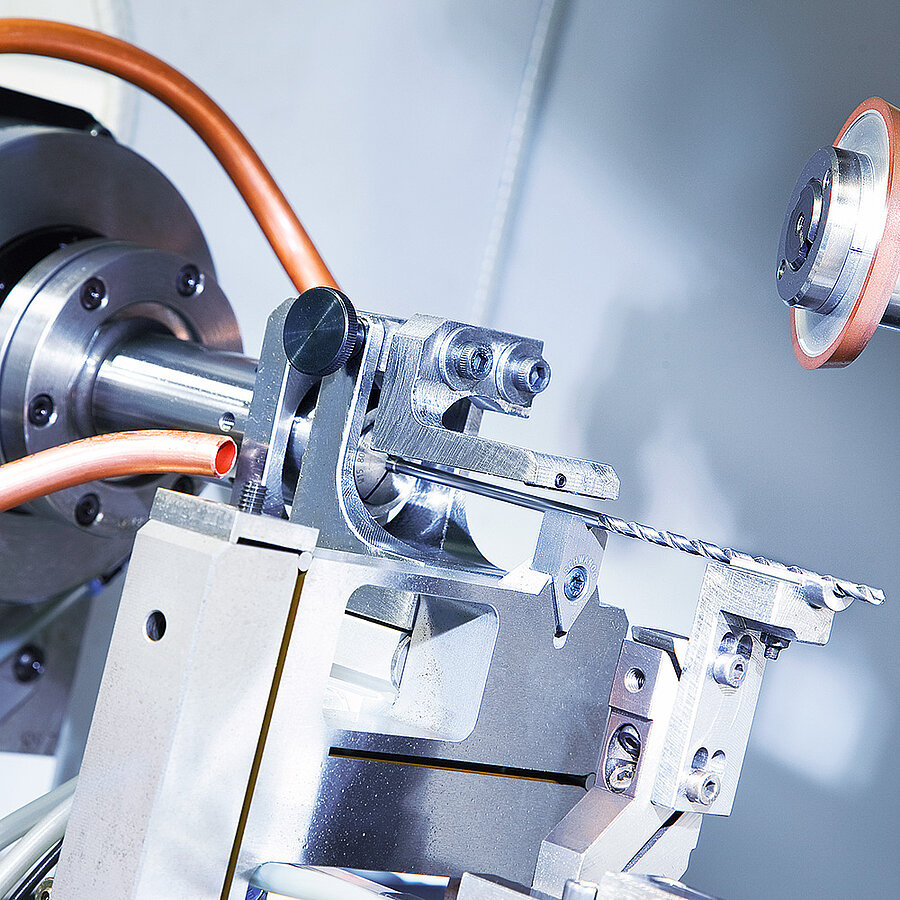

To ensure perfect preparation for all workpiece versions, the 335linear can be equipped as an option with one or two auxiliary slides. Depending on the requirement, these slides are suitable for building up a support, a tailstock or a tool guidance system. It is also possible to combine two of the above-mentioned clamping aids on a slide. You therefore also have all clamping options at your disposal for future requirements and safeguard your investment in the long term.